COST-EFFECTIVE FLANGING

ECKOLD systems, like the mobile formers, offer several features to improve and optimize the production of containers and vessels.

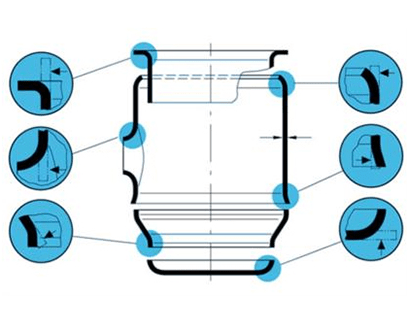

Flanging means step by step bending of the rim of a cylinder, container or tank end. A complete flanging unit consists of the drive unit, the mobile tool and the interchangeable inserts. The mobile tool is selected according to the sheet thickness and flange heights required.

Four flanging tools are available, covering a material thickness range from 2.0 mm to 15.0 mm (m.s.) with flange heights between 10 and 50 mm (depending on diameter and material thickness). The tools are mainly used in tank and container building for the chemical and petrochemical industry, the food industry and for distillery equipment.

The advantages:

- Extremely low noise level

- Without heat applied

- One man operation

- Can be operated on the work-/assembly site

- Precise fitting

- Universal