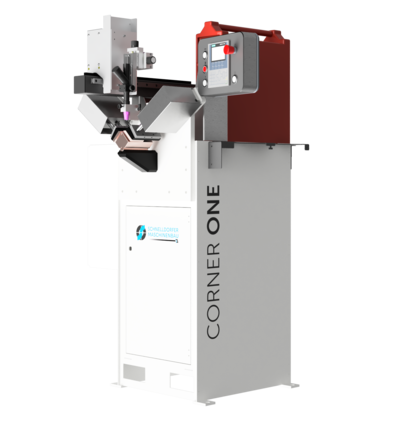

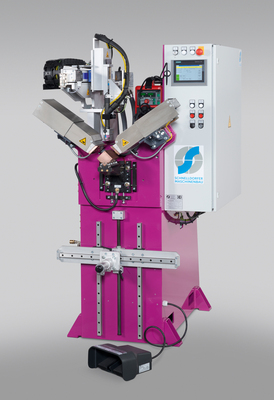

Our Cornerweld type standard and special welding machines make welding of simple and rear-lipped corner seam profiles on various parts easier and more precise than ever.

CORNERWELD corner welding machines have been developed for welding of plates in a 90° joint. Precise clamping technology with cooling and shielding gas supply combined with a convenient machine control for control of welding cycles ensure high-quality corner welding seams.

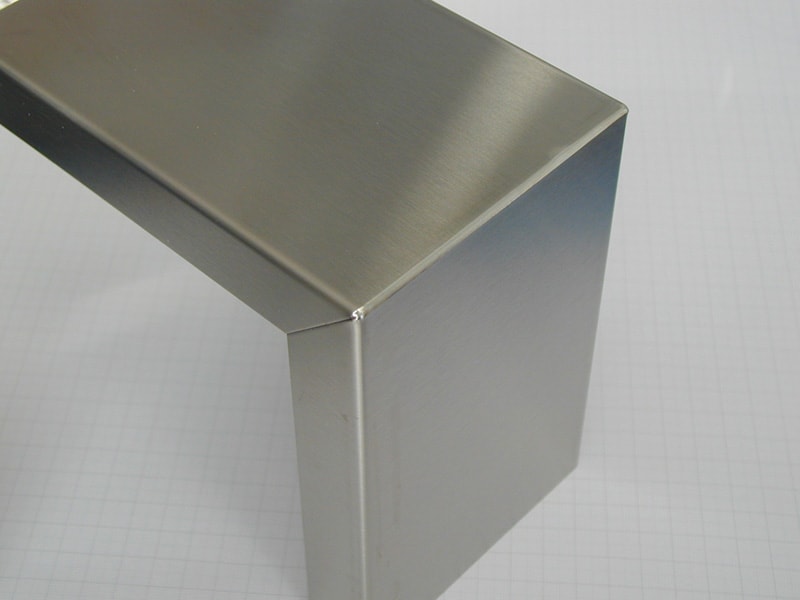

With stainless steel, uniform, visually perfect corner weld seams with no discolouration are possible. Particularly corners made of lipped pieces of cut stainless steel with ground, brushed or even a marbled surface will have a clean look with no regrinding.

0,5mm – 2mm

0,5mm – 2mm até 320mm

até 320mm