0,3mm - 3mm

0,3mm - 3mm 600mm - 1300mm

600mm - 1300mm 60mm - 980mm

60mm - 980mmApplication examples:

0,15mm – 0,8mm

0,15mm – 0,8mm 250mm - 1000mm

250mm - 1000mm 15mm - 1050mm

15mm - 1050mmApplication examples:

0,2mm – 1,5mm

0,2mm – 1,5mm 200mm - 1600mm

200mm - 1600mm 25mm - 1050mm

25mm - 1050mmApplication examples:

0,2mm - 3mm

0,2mm - 3mm 200mm - 1600mm

200mm - 1600mm 25mm - 1050mm

25mm - 1050mmApplication examples:

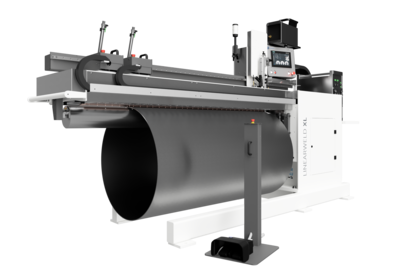

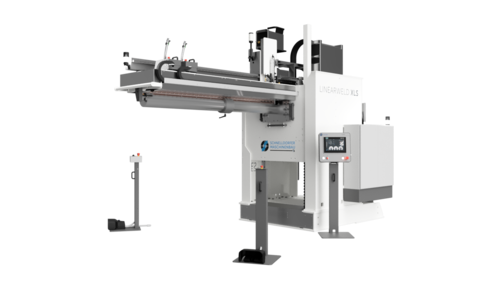

0,5mm - 15mm

0,5mm - 15mm 600mm - 4120mm

600mm - 4120mm 80mm - 1050mm

80mm - 1050mmApplication examples:

0,5mm - 15mm

0,5mm - 15mm 1600mm - 4120mm

1600mm - 4120mm 145mm - 5190mm

145mm - 5190mmApplication examples:

0,5mm - 15mm

0,5mm - 15mm 2100mm - 4120mm

2100mm - 4120mm 225mm - 1050mm

225mm - 1050mmApplication examples:

0,5mm - 15mm

0,5mm - 15mm 2100mm - 4120mm

2100mm - 4120mm 225mm - 5190mm

225mm - 5190mmApplication examples: